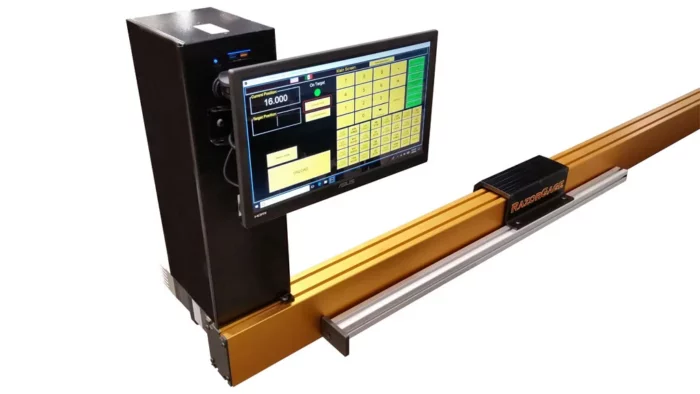

Razorgage ST Automatic Saw Measuring System

PROGRAMMABLE SAW STOP & PUSHER

The RazorGage ST Automatic Saw Measuring System is at the heart of our product line. Whether you use the ST as an automatic pusher or an automatic saw measuring stop, this digital saw stop and measuring fence can be used with a chop saw, upcut saw, downcut saw, drill press, haunching, notching and punching machines. When looking to improve output and efficiency for your operations, the RazorGage ST Automatic Saw Measuring System offers the highest degree of accuracy, repeatability and long-lasting dependability.

If you have questions or would like more information, please fill out our contact form.

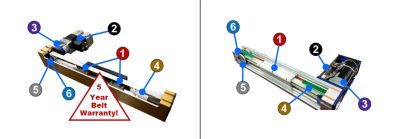

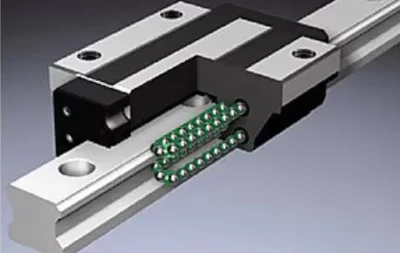

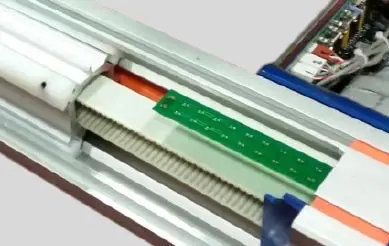

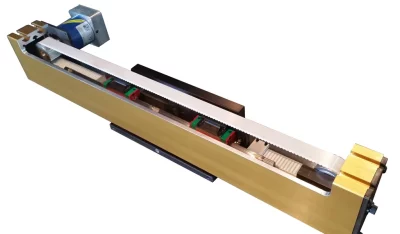

The carriage assembly features a Hiwin hardened and ground linear bearing rail with two recirculating ball bearing blocks — just like you see on CNC machine tools and machining centers. This enables nearly friction-free motion, maximum rigidity, accuracy and long life. The RazorGage ST can be used for automatic chop saw measuring, or it may be installed for use alongside other types of saws.

Learn more about the superior hardware used in the construction of the RazorGage ST programmable saw stop.

RazorGage ST Automatic Positioner Software

Our industry leading software is powered by Microsoft Windows so networking and file sharing is no different than any other PC in your office, home, or shop. Since the RazorGage software is based on a rapid development platform, it is constantly evolving to meet the needs of our customers and can be easily customized.

The Windows application software for this digital saw stop provides a bright, bold user interface with intuitive functionality. Setup and calibration functions are intuitive and just a screen touch away. Built-in functions such as fraction keys, presets pages help eliminate operator mistakes and improve productivity.

RazorGage ST Digital Saw Stop Features

- PC running the Windows 10 Professional OS with a hi-resolution touchscreen networks easily with other devices using ethernet or WiFi and has tons of features.

- Optional Tower PC with a hi-resolution touchscreen and larger electrical enclosure for extra control components.

- Store thousands of cutlists, sort cutlists into thousands of groups according to multiple criteria.

- Fraction keys allow the user to adjust position in just a few keystrokes.

- Optional optimizing software reduces waste material.

- Print labels with text and a combination of any two special fields that can each contain barcodes, QR codes, or images.

- Single Cutlist Mode allows synchronization with server databases.

- Uses the same linear bearings found on CNC machine tools.

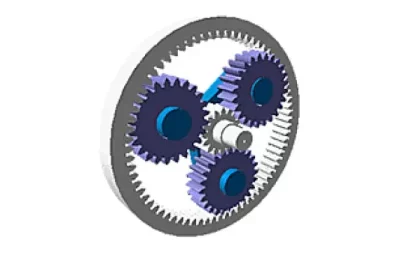

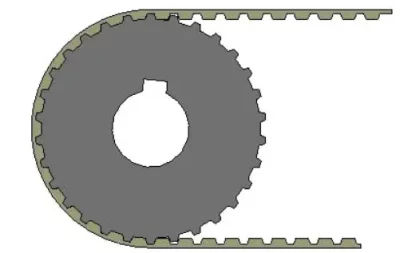

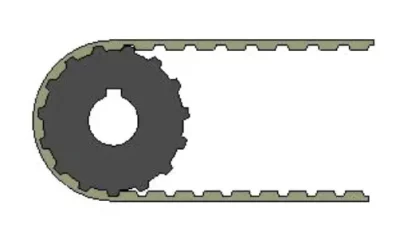

- Near zero backlash planetary gearhead & drive pulley.

- 5 Year Belt Warranty.

- Available in stroke lengths up to 60’.

WHAT SETS RAZORGAGE PROGRAMMABLE SAW SYSTEMS APART

If you’re investing in an automatic saw measuring system, you want a product that is dependable every single day. Replacing parts and paying for repairs will cut into your ROI. To get the most out of your new programmable saw positioner, choose one with superior components made of high-quality materials.

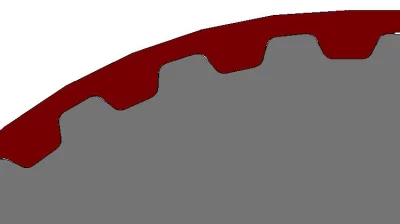

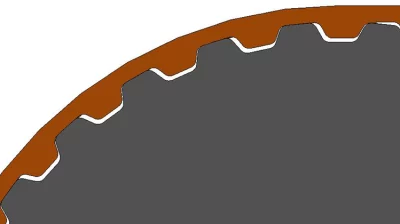

For example, the positioning carriage on a RazorGage automatic saw system is mounted on recirculating ball bearing blocks rolling on hardened steel. Competitors use plastic and aluminum — materials that are much more prone to inaccuracy and wear. RazorGage components are designed to minimize backlash, reduce wear and ensure a high level of accuracy and consistent performance time after time. By comparison, our competitors’ components are lower quality, and it shows in the overall poorer performance of the positioner.