Razorgage Anglemaster

AUTOMATED ANGLE SAW SYSTEM

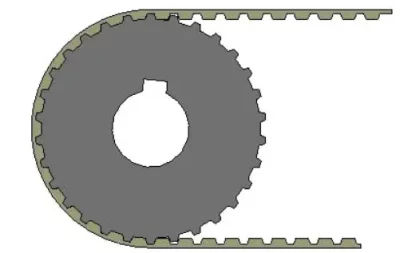

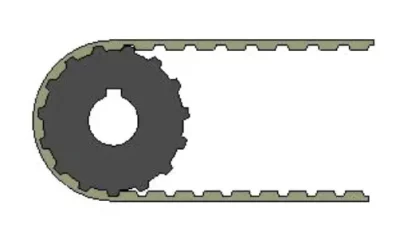

Looking for a saw that cuts angles? The RazorGage AngleMaster is a semi-automatic miter saw fence system that automatically adjusts to cut your leading and trailing angle. The AngleMaster angle saw software with integrated AutoList combines with the computerized miter saw hardware to enable effortless, accurate angle cutting.

If you have questions or would like more information, please fill out our contact form.

Using the AngleMaster Semi-Automatic Miter Saw

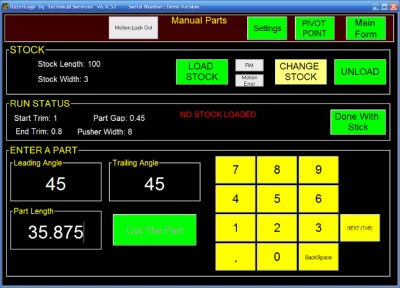

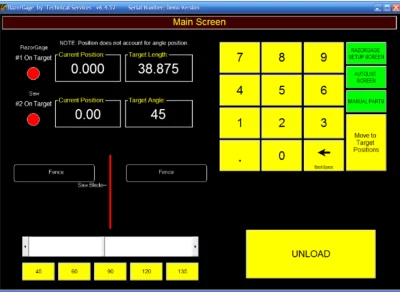

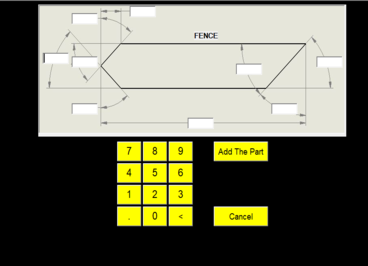

The operator selects a cutlist from those downloaded from the office or manually enters the leading and trailing angles, length, & width, required for a single part. The RazorGage positioner advances the material and rotates the saw to the correct leading angle. The operator makes sure the clamps are adjusted correctly, cycles the saw, clears any small jamb-prone drops from the table and clicks DONE on the hi-resolution touchscreen. The RazorGage positioner then advances the material and rotates the saw to make the trailing edge cut. Once positioning of material and blade is complete the operator makes sure the material is against the fence and the pusher, engages the clamps, and cycles the saw. Repeat the process.

At RazorGage, safety is our top priority. To use the AngleMaster computerized miter saw, the operator must clear each cut part and drop before the machine will advance the material for the next cut. Using the hi-resolution touchscreen interface to control the AngleMaster is simple and intuitive.

Other safety features include the two-hand anti-tie down buttons. After ensuring that the clamps are not in the path of the saw blade and the blade has automatically rotated to the proper angle, the operator uses the two-hand anti-tie down buttons to cycle the saw. This unique safety feature protects operators and prevents potential accidents.

Automatic Miter Saw Fence

Software Options

Standard AngleMaster Angle Saw Software

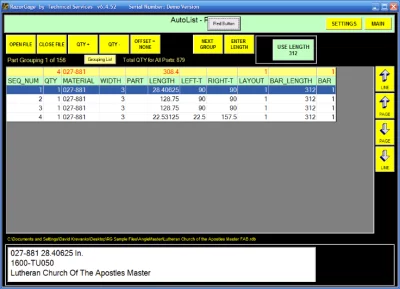

The RazorGage ST with AutoList software and the AngleMaster software, are integrated into all RazorGage AngleMaster semi-automatic miter saws.

AngleMaster Auto90 Package

Other saw manufacturers may try to conceal this fact, but the reality is that problems occur when trying to cut angled parts in an automatic pusher mode. In most applications, 80% of the parts going through the saw are cut at 90°. Parts cut at other angles can cause jams and other issues.

We developed the AngleMaster Auto90 angle saw package to address the issues associated with cutting materials at angles other than 90°. Unlike other saws that cut angles, the AngleMaster with Auto90 package is designed to prevent jams. So, how does it work?

- Upon opening the cutlist, the software automatically sorts the parts into groups.

- When cutting a group in which all the angles are 90°, the AngleMaster Auto90 runs that group in full auto mode.

- When there are parts with different angles in a group, it runs in semi-auto mode so that the operator can clear pesky drops prone to jamming the machine.

Please note: AngleMaster Auto90 package does not come standard with AngleMaster angle saw systems. Please let us know if you are interested in purchasing this upgrade to your AngleMaster system.

AngleMaster Computerized Miter Saw Features

- Windows Tower PC operation on a large, color hi-resolution touchscreen monitor

- Download cutlists directly to the RazorGage AngleMaster computer via Wi-Fi or wired Ethernet cable

- Store thousands of cutlists on the computerized miter saw software. Optimize and sort cutlists into thousands of groups according to various criteria

- Label printer option available

- AngleMaster Angle Saw System comes with a PVC table top, but optional steel or PVC rollers are available

- Optional articulated pusher mounted gripper

- Blade mist lubrication standard for cutting aluminum

WHAT SETS RAZORGAGE PROGRAMMABLE SAW SYSTEMS APART

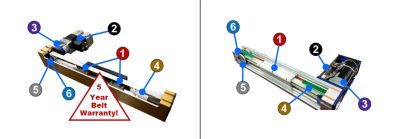

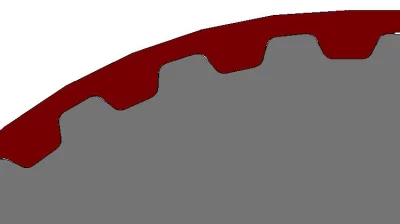

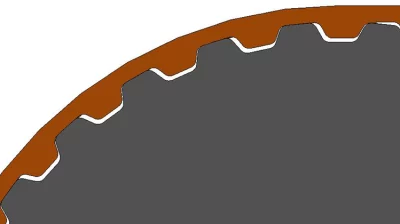

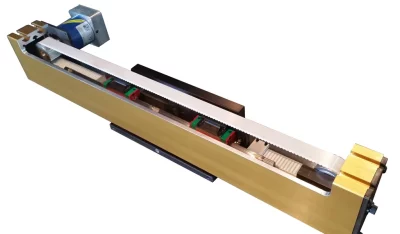

If you’re investing in an automatic saw measuring system, you want a product that is dependable every single day. Replacing parts and paying for repairs will cut into your ROI. To get the most out of your new programmable saw positioner, choose one with superior components made of high-quality materials.

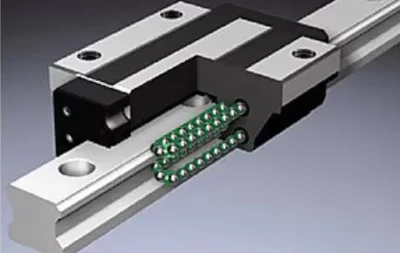

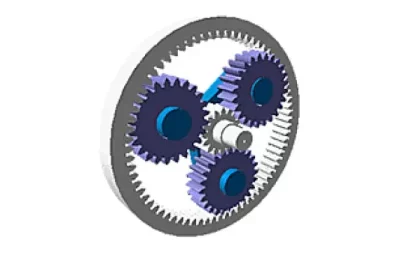

For example, the positioning carriage on a RazorGage automatic saw system is mounted on recirculating ball bearing blocks rolling on hardened steel. Competitors use plastic and aluminum — materials that are much more prone to inaccuracy and wear. RazorGage components are designed to minimize backlash, reduce wear and ensure a high level of accuracy and consistent performance time after time. By comparison, our competitors’ components are lower quality, and it shows in the overall poorer performance of the positioner.