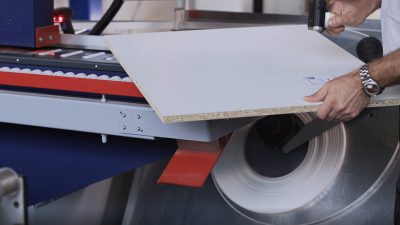

Ott Tornado Plus

Dependable, compact and versatile. Our Tornado+ - following the bestseller Tornado and Tornado Top - is in in high demand. The compact build and the flexibility of the machine make it the perfect solution for modern carpenters. Tornado+ can be turned into a full edgebanding center in combination with TransCompact

If you have questions, or would like more information, please fill out our contact form.

Product Info

Technical Data:

- Compact edgebander for precise processing of coiled material up to solid lippings

- For edge thickness from 0.3 mm up to 15 mm

- Panel thickness up to 60 mm

- Machine length: 5.7 m

- With highly efficient Beckhoff industrial PC and 18.5" touch screen

Video

Basic Configuration

- CombiMelt gluing system for EVA and PUR with 1.5L container and filling pipe

- PLC controlled with 18.5-inch color touch screen

- Pre-milling unit

- Automatic edge magazine

- Automatic coil magazine with guillotine

- Double end trim, automatic tilt from 0 to 3 degrees

- Rough trim

- Fine trim

- Automatic corner rounding

- Contour scraper with extraction

- Flat scraping unit

- Spray mist device for release agent applied to panel prior to the pre-mill station

- Spray mist device onto edge surface for sensitive edge materials

- Burring unit

- Nesting option for pre-drilled panels

- Electrical-UL

Available Options

Available Options

- Heated infeed guide

- Infeed slide pusher for panels

- Air cushion table with vacuum generator; to be positioned at feed entrance (dimensions: 1800 x 600mm)

- PCD tools for pre-milling 85mm dia. 62mm height

- Coil magazine for 2 coils

- Two position automatic edge selection (automatic height adjustment)

- High gloss set, allows for flush trimming of panels with protective film with protective film without the operator making manual copy wheel adjustments

- Two position automatic scraper changer

- Set of quick-change motors

- Set for narrow pieces (60mm), support rollers for machining narrower parts, distributed over machine length

- Equipment for 20 meters/minute feed speed

- Preparation for later installation of a panel return system

- Spray mist nozzles for antistatic agent

- Structure brushing unit

- Sanding unit

- Horizontal aggregate grooving unit

- Vertical aggregate grooving unit

- Synchro-Flex, driven belt top pressure, synchronized with feed

- Narrow part package, support rollers for machining narrower parts, distributed over machine length

Specs

| Machine Length | 5,65 meters |

| Infeed Speed | 12-18 meters/minute (corner round in 18 meters) |

| Edges Applied | ,3 to 15mm |

| Panel Length | 150mm |

| Panel Width | 80mm |

| Panel Thickness | 8-60mm |

Downloads

If you have questions, or would like more information, please fill out our contact form.