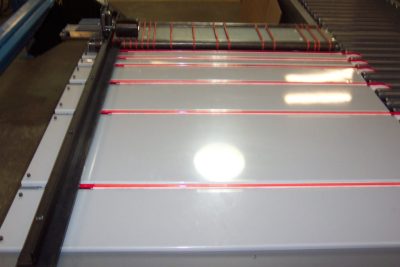

Taylor #911A- Taylor Return Conveyor for Shaper Sander

The Shaper Sander model comes in multiple widths and lengths. The return can be made to match the length of your machine, and special slanted outfeeds have been designed to miss squaring bars and such on Shape & Sands.

Features:

- (4) machine lengths return material up to 60″, 96″, 112″ long, or 132″ Long

- Heavy duty frame and component construction for long life(Heavier than the competition)

- Fixed Catch Area

- 24″ or 36″ Rollers on return conveyors can handle up to 36″ or 50″ wide material.

- Optional 48″ Catch Rollers

- Minimum material size 1″ x 6″

- Roller Spacing 3″ center to center

- All rollers are powered and individually clutched for long belt life.

- Any Length Return (in one foot increments, measured from tail end of shaper/sander) composed of modular sections.

- Return is 2 1/2″ lower than receiving conveyor, allowing for over/under return.

- Variable Speed AC drive matches conveyor feed rate to edge bander feed rate.

- Adjustable Height to match pass line height of the Shaper Sander

- Compatible with many brands of Shaper Sander

Return Conveyors on a Shaper Sander have a fast payback. Most doors or panels need at least 2 passes, if not 4, through the machine to be fully machined. This normally would require (2) Operators, one to feed, and one to catch. With a Taylor Return, productivity is increased by 100% or more because it makes a (2) operator job into a (1) operator job.

- Return on Investment: With our competitive pricing, the payback period is very fast. The cost of a new machine is typically less than one year’s wages.

- Quality and Innovation: Taylor’s 105 years in business and our four Challenger Awards assures a U.S.-made machine high on quality and long on innovation

- Fast Delivery and Easy Setup: All machines are built in our Upstate New York factory in eight weeks or less. Every machine is fully assembled here and ships 80-90% assembled. You will be up and running in hours

- Sales and Support: Because we design, build, test and ship at one facility, we understand the needs of the customer. Year in and year out, we are regarded as one of the best sales support companies in the woodworking industry

When you buy a Taylor Return Conveyor, you buy more than a machine, you buy into a company that partners with you to make your company productive. Cameron Automation is a division of James L. Taylor which has served the woodworking industry for over 100 years. In that time, we have developed and maintained a level of customer service and products that are second to none.

Our machines are American made. From where Terry unloads raw steel from trucks to where Monty packs a completed machine for shipping, it’s all done here in the US. We maintain a large inventory of parts ready for next day delivery. We support our customers with an available and knowledgeable service staff. Our service is second to none. Just ask any of our thousands of satisfied customers