Taylor #713A-M Miter Door Pro

(5) Section Machine: 250+ Miter Cabinet Doors per day

(8) Section Machine: 400+ Miter Cabinet Doors per day

(5) Section Miter Door Pro:

The (5) Section Door Pro is designed for the small or medium shop that like to produce their own doors. Capable of clamping and curing doors quickly, this machine can be used for a few hours a day, or all day long, depending on the number of doors that need to be produced. With the quick change over design of each section, clamping doors (1) Kitchen at a time can be done effectively and efficiently.

How it Works:

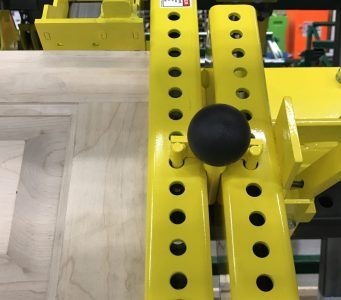

In a typical door shop glue is applied and components assembled on an assembly table. The door is placed in a section and clamps adjusted. The cylinders are activated by one valve which brings pressure in on all (4) corners at the same time to clamp and square the Miter Door. Fine adjustments to the corners can be made by dialing the pressure BOTH in and out with the innovative dial regulator system that comes standard on a Miter Door Pro.

A motor drive is used to rotate the next section. The cured door is removed and new components are placed in that section for clamping. Our 5 section Door Pro can produce up to 250 doors in an 8 hour shift. This equates to approximately 2.5 minutes per door and a clamping time of 12 minutes.

(8) Section Miter Door Pro:

The (8) Section Taylor Door Pro clamping system is designed for the medium to large door shop that clamps either large door production runs or a kitchen at a time. Our design lends itself to fast changeovers, so switching from Door to Door easy and efficient. This will keep a high production rate in a one piece workflow style of manufacturing.

How it Works:

In a typical large door shop glue is applied and components assembled on an assembly table by an Operator. The door is placed in a section and clamps adjusted by a 2nd operator. The cylinders are activated by one valve which first creates side pressure pushing the door to the left side square, a second later the vertical clamps are activated to create pressure on the glue joints. The first operator works on the next batch of parts by applying glue and loosely assembling the door while the second operator quality checks the door under pressure and wipes away any excess glue.

A motor drive is used to rotate the next section. The cured door is removed and new components are placed in that section for clamping. Our (8) section Door Pro can produce up to 400+ doors in an 8 hour shift. This equates to approximately 1 minutes per door and a clamping time of 8 minutes.

Features:

- Standard Machine Models

- (5) Rotating Sections (Small to Medium Shops)

- (8) Rotating Sections (Medium to Large Shops)

- Section Capacities:

- Standard Machine = 26″ x 62″ Maximum Clamping Capacity

- Large Capacity Machine = 38″ x 96″ Maximum Clamping Capacity

- Innovative Dial Regulator System for Miter Doors

- Operators can Dial in Desired Clamping Pressure to Precisely and Accurately Square any Type of Miter Door

- Each Clamp can Dial Pressure IN or OUT to Make Fine Adjustments in Each and Every Corner

- Heavy Duty Diaphragm Cylinders Provide up to 1500 lbs of Clamping per Clamp

- Door Pro Frame is made of 100% Steel Construction

- Electric Gear Motor Provides Counter Clockwise Rotation for Operator Safety

- Single Button Control Box Activates Rotation and Includes Auto Index Feature

- Precisely Square and Clamp Stile & Rail Doors Too!!

- Includes a (1) Year Manufacturers Warranty

The Taylor Door Pro was a natural progression from the JLT Single Door Clamp. We have installed hundreds of machines in shops across North America. Machines come in (5) and (8) station models and some customers order an (8) station frame with (4) stations installed. This provides for easy expansion in the future.