No Melt Saw Blades for Plastic Sheets and Extrusions

The NO-MELT carbide-tipped saw blade is especially designed for cutting single or multiple stacked sheets of plastic without chipping or melting these materials. NO-MELT blades are particularly suitable for acrylics, delrins, ABS, styrenes, PVC, and both high and low melt nylons. Specially engineered side clearances on the carbide teeth significantly reduced and in many cases, totally eliminate any formation of melted burrs or buildup of residue on cross-sawn sections or plastic materials.

Made with DOUBLE-HARD and 40% stronger C4 Carbide. 50% to 300% Longer Life Between Sharpenings

• Reduced Yearly Sharpening Costs

• Less Machine Downtime

• Improved Labor Efficiency

• Improved Labor Efficiency

• Inventory Savings

• Fewer Blades Required

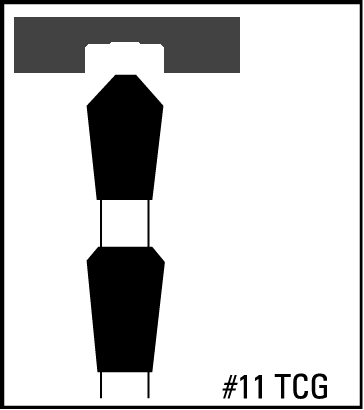

The large number of carbide teeth with a special modified triple-chip-grind (#11 tooth style) allows fast feeding of brittle acrylics with no chipping. On table saw, raise blade to cut cooler, lower blade to prevent chipping.

Thinner sheets use more teeth, and thicker sheets use less teeth:

3/32″ – 1/8″ thickness use 80 teeth

1/4″ – 1/2″ thickness use 60 teeth