Altendorf F5 Edgebander

If you have questions, or would like more information, please fill out our contact form.

Anyone who sets high standards cannot make any compromises. The Hebrock F 5 reliably produces perfect edges – from material cuts to touch-up work. The best features for the best woodworking.

If it’s maximum performance you want, the Altendorf F 5 is the solution for edgebanding in demanding workshop operations. The F 5 guarantees edge finishing in all stages and directions, as it is fitted with all the components you need for your requirements: Pre-milling aggregate, trim saw, top/bottom trimming, radius profile scraper, corner rounding unit, surface scraper, buffer unit. For even more flexibility on the way to the perfect finish, the F 5 can also be optionally fitted with a practical multi-radius profile scraper.

- Max. edge thickness: 3 mm

- Max. workpiece thickness: 50 mm

- Min. workpiece length: 160 mm

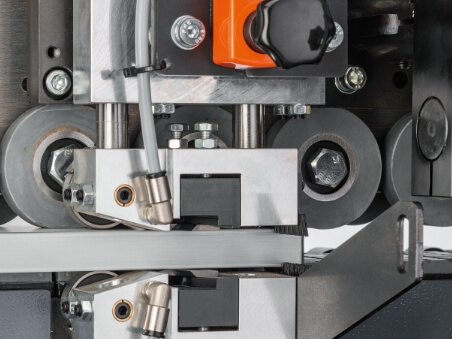

Pre-milling Aggregate

End Trim Saw Unit

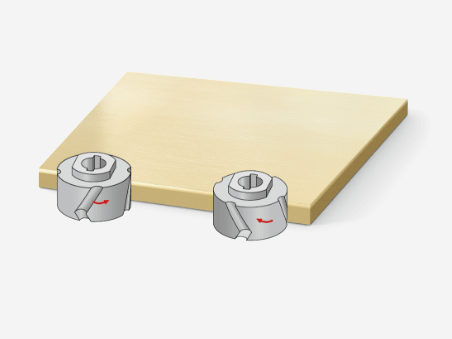

Top and Bottom Trimmer Unit

Radius Scraper Unit

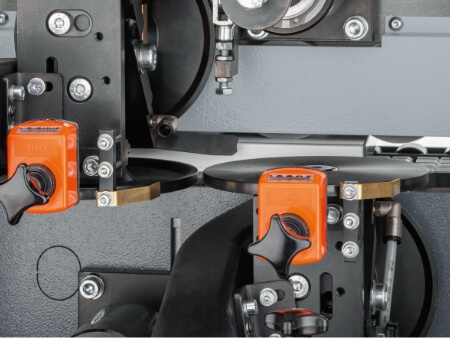

Corner Rounding

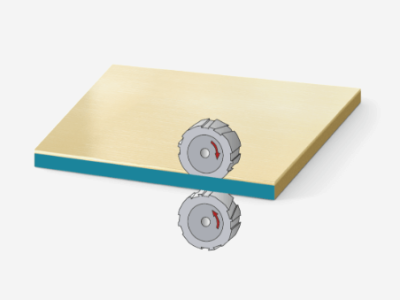

Surface Scraper

Multi-radius Profile Scraper (Optional)

Further equipment:

- PLC control with 10” touchscreen

- Top-side fast-heating glue pot (maintenance-free)

- Support plate for edge material

- Automatic central lubrication (trim saw, corner rounding unit)

- Visual display for workpiece sequence

- Workpiece support (folds out to front)

- Pot interchange mount incl. adhesive interchanger for PUR processing

- Surface scraper with dual-tracing

- Pneumatic roll cutting station (shears-type design, Hebrock system)

- Pot interchange mount incl. adhesive interchanger for PUR processing

- Surface scraper with dual-tracing

- Pneumatic roll cutting station (shears-type design, Hebrock system)

Technical Specifications

F 5 - TECHNICAL SPECIFICATIONS

| Max. edge thickness | 3 mm |

| Min./Max. workpiece thickness | 8 – 50 mm |

| Min. workpiece length | approx. 160 mm |

| Feed speed | 7 m/min. |

| Ready to operate | approx. 3.5 min. |

| Power consumption | ∅ approx. 7.4 kW |

| Electrical connection | 400 V/3 phase/50 Hz |

| Table height | approx. 900 mm |

| Machine dimensions | approx. 4,300 x 1,300 x 1,400 mm (LxWxH) |

| Weight | approx. 900 kg |

| Exhaust connection | ∅ 1 x 140 mm |

F 5 - SPECIFICATIONS AND OPTIONS

| Options & feature packages | |

|---|---|

| Workpiece support (folds out to front) | • |

| Pneumatic roll cutting station (shears-type design, Altendorf system) | • |

| Automatic central lubrication (trim saw, corner rounding unit) | • |

| Double roller overhead pressure system (ball-bearing mounted) | • |

| Conveyor chain with permanently attached special links | • |

| PLC control with touch screen (10“) | • |

| Pre-milling aggregate | • |

| Top-side fast-heating glue pot (maintenance-free) | • |

| Pot interchange mount including adhesive interchanger for PUR processing | • |

| Trim saw | • |

| Top/bottom trimming | • |

| Radius profile scraper | • |

| Multi-radius profile scraper | ο |

| Corner rounding unit | • |

| Surface scraper with dual-tracing | • |

| Buffer unit | • |

| Support plate for edge material | • |

| Visual display for workpiece sequence | • |