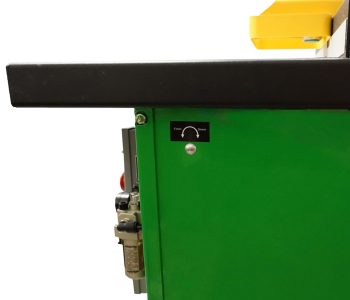

TSM-30 Series Pocket Cutters

TSM-30s are extremely well-suited for multi-shift production in a broad variety of woodworking manufacturing environments.

Designed for continuous production in cabinet manufacturing, furniture plants, mobile home factories, and more. The TSM-30 Series Pocket Cutters are available in three different voltage options: 220V Single Phase, 230V Three Phase, and 460V Three Phase. Each cuts the patented, six-degree, Castle low-angle pocket. TSM-30s are extremely well-suited for multi-shift production in a broad variety of woodworking manufacturing environments.

Heavy duty induction motors drive the pocket cutting spindle: the TSM-31 uses a 220V, single phase induction motor and the TSM-35 models use three phase induction motors in either 230V or 460V. All models use a high-torque, heavy-duty air motor - specifically designed for Castle - to drive the pilot bit. Both operations - pocket cutting and pilot hole drilling - are completed in a single cycle.

TSM-30 series feature heavy duty construction throughout, with easy, top-down access for quick tooling changes. Adjustable indexing stops are built into the top for quick part transitions during high production shifts. These premier woodworking shop tools can produce more than a quarter million pockets per month for years on end with minimal maintenance.

Features and Benefits Include:

- Cuts the Castle low-angle pocket, for strong, stable, tight, and superior joints – even in ½” material!

- Designed for high-capacity, continuous production joinery for maximum throughput of parts and components

- Low-angle pockets minimize the need for clamping during assembly

- Cuts pocket and pilot hole in a single cycle, increasing throughput and decreasing material damage and waste

- Standard machine height with a small footprint - easy to fit into any production line

- Easy maintenance and bit changing

- Minimal shop air required: 85 psi

- Footswitch with automated operation that’s simple and easy to use

- TSM-30 series machines quickly integrate into any existing manufacturing process or workflow

Technical Specifications:

- Motor: 1.5hp Baldor Router Motor (TSM-31 220V), 1hp Leeson Router Motor (TSM-35 230V and TSM-35 460V)

- Drill: Sioux SDG10S25FCT Air Motor

- Router bit: Premium 3/8″ Solid Carbide, Rough Mill

- Drill bit: Premium 9/64” Brad and Spur TiN-Coated Bit

- Power Options: 220V Single Phase; 230V Three Phase; 460V Three Phase

- Air req: 85 psi—external regulator, filter and lubricator included

- Basic footprint: 21″ depth x 19″ width

- Working height: 36.5″

- Worktop usable area: 16″ depth x 18.5″ width

- Machine height: 38″

- Shipping weight: Approx. 340 lbs

- Shipping dimensions: 22″ x 28″ x 52″

- Manufactured in USA