Spectrum Series

If you have questions, or would like more information, please fill out our contact form.

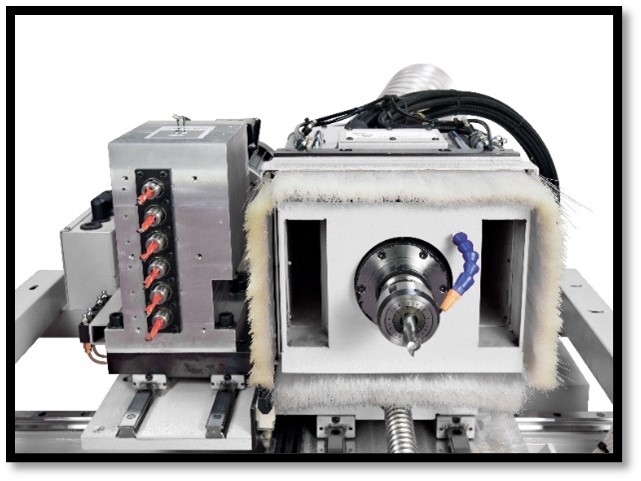

The Spectrum is fully equipped with the highest quality control components from Fanuc. It is a moving gantry (stationary table) type machine equipped with 1 (one) 12 HP 4-pole air-cooled router spindle, with grease lubricated ceramic bearings, a 6-Position Static Automatic Tool Changing System, with tool length touch probe, and 1 (one) 2 HP, multiple spindle boring unit with 6 independently selectable spindles for vertical boring. The spindle motor is powered by an electronic AC inverter drive system with dynamic spindle braking. Full Torque is achieved at 9,000 RPM & Full HP is achieved at 12,000 RPM.

The Static Tool Changer Pick Up Station, with Steel Tool Holder Clips, is mounted at the back of the machine, for fast and efficient tool change operations.

The bridge & vertical supports are monolithic one-piece construction for maximum stiffness and accuracy.

The X & Y axes are constructed of massive, heavy duty welded steel construction with multiple reinforcements to increase strength and absorb vibration. Z-axis spindle carriage is a specially designed Meehanite casting for high strength and inherent vibration dampening characteristics with a pneumatic counterbalance system for smooth and accurate operation.

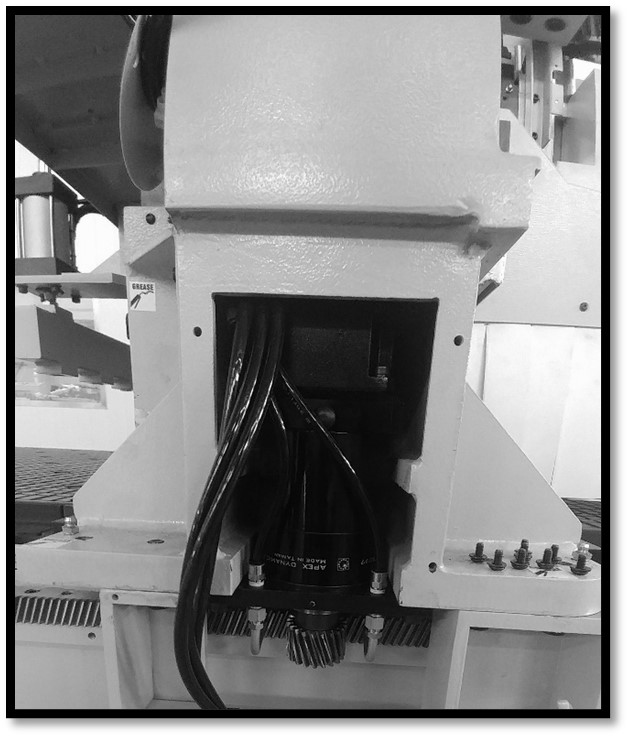

Hardened and precision linear guide way systems with recirculating roller linear bearings are provided for all primary movements in the X, Y & Z axes. Hardened and precision ball screws with anti-backlash ball nuts are provided for all primary movements of the Y & Z axis. The X-Axis is a dual drive, dual support, 2-channel system, using twin industrial grade, induction hardened, helical racks & pinions.

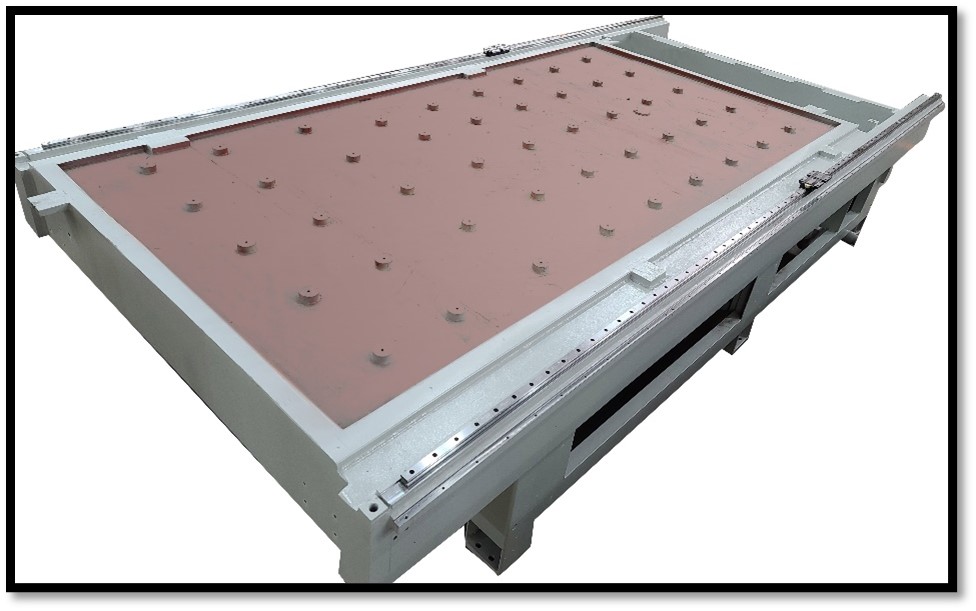

The vacuum table is made of torsion resistant cast steel, covered with a 30mm thick phenolic grid table top for the quick and easy mounting of work pieces via pods, clamps, spoil-boards, or holding fixtures.

THREE (3) pneumatically controlled Pop-up pins are included for sheet location and for Nested Based Manufacturing.

The table is configured with ONE (1) vacuum zone, which is automatically m-code controlled. The vacuum zones are equipped with an electronic safety barrier & low vacuum sensor. This table & pump combination allows a wide range of flexibility in holding large & small work pieces.

Centrally located grease fittings are utilized for X, Y, & Z Axis and profiled linear guide ways. All guides are protected from dust and other contaminates by double sealed wipers. The operator control panel is mounted on a control arm, in front of the machine, and has a Handheld Pendant with separate Feed Rate and Rapid Rate Override for easy access by the operator. A dust collection hood with automatic damper system is provided for the router spindle & for the drilling block.

State-of-the-art closed loop FANUC AC digital servo motors are utilized on X, Y & Z axis. The FANUC Electronics and controls systems are placed into a covered & sealed electronics cabinet that is conveniently located at the back of the machine base. This space saving design eliminates many of the wires that would otherwise be stretched across your floor.

Why you should consider Anderson the #1 choice

- 1000 CNC Machines manufactured per year

- World’s Leader in PCB Manufacturing CNC Machines

- Over 4500 CNC machines installed in North America

- Reputation for reliability---2 Year Warranty

- All inclusive pricing includes freight, tool holders, chuck-nuts, collets, vacuum, training & installation

- Local service in most areas

- Lifetime Phone Support

- Lifetime Remote Online Diagnostics Support

- Standard with Fanuc Controller, Drives, and Servos

- Benefits of FANUC

- Standard control for CNC industry Up to 30,000 controls manufactured per month

- Economies of Scale in Manufacturing Up to 200,000 servos manufactured per month

- Cutting Edge technology Provider Up to 2500 robots manufactured per month

- 194 Parts & Service Centers Worldwide with 34 Parts & Service Centers in the US

- 25 Year Parts Availability Guarantee

- 600 Engineers in Research & Development

- Over 700,000 Model 0i controllers installed worldwide

- Over $5 Billion in annual sales

- Average Mean Time Between Failures (MTBF) of 27 years

- 2 Year Parts & Labor Warranty

- Available Extended FANUC Warranty for years 3 thru 10

Technical Specifications

| Pop-up positioning pins | 3 – 60mm pins |

| Vacuum Zones per Table | 3 (three) - optimized for 4x8, 5x10, & 5x12 |

| X Axis | 200 mm (8”) |

| Maximum Feed Rate X-axis | 60 meters/min (2,360”/min) |

| Maximum Feed Rate Y-axis | 60 meters/min (2,360”/min) |

| Maximum Feed Rate Z-axis | 20 meters/min (787”/min |

| Maximum Rapid Traverse All -axis | 84.85 meters/min (3,341”/min) |

| Router Spindle type | 12HP Anderson Air Cooled |

| Motor power | 12 HP (S6): 10 HP (S1) |

| Spindle speed (RPM) | 1000-21000 |

| No. of changeable tools | 6 |

| Spindle nose | HSK63F taper |

| HSK 63F tool holders | 6 sets (Holder & Locknut) |

| Aggregate Torque Ring | INCLUDED (for compact aggregates only) |

| Collet Sizes Included | (2) ½”, (2) 3/8” (1) ¼” & (1) ¾” (total # of collets: 6) |

| Line Boring Unit | 2 HP |

| Spindle speed | 4500 rmp |

| Vertical drills | 6 x 1 |

| Drill shank dia. | 10mm |

| Vacuum hold down system | 2 (two) Becker Pumps with H-Rack |

| Power (per pump) | 9 HP |

| Flow (per pump) | 168 cfm |

| Total Pressure | 24" Hg |

| Machine Height | 98.5" |