Altendorf WA 80

Fascinating performance

The WA 80 enables you to successfully take on any material challenge: no matter whether you are working with wood or plastic. With its well thought-out design and robust build quality, it makes light work of simple but precise squaring cuts through complex angles. Completely developed and assembled in Germany, the machine sets a new benchmark for sliding table saws in terms of price and quality. It will guarantee the success of your business.

If you have questions, or would like more information, please fill out our contact form.

The Altendorf WA 80

Uncompromisingly strong, precise and reliable. The WA 80 stands for unique stability and the highest level of production safety. These qualities make the WA 80 the ideal partner for your successful projects.

- Max. cutting length 4,300 mm

- Max. cutting height 150 mm

- Max. cutting width 1,300 mm

An overview of the key features.

Control panel on the machine frame

You can control the height and tilt adjustment of the main saw blade at the press of a button. The tilt angle is shown on the digital display.

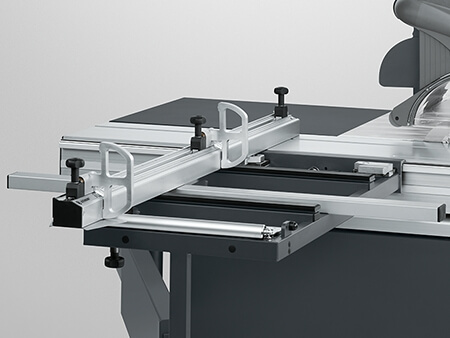

Rip fence with precise manual adjustment

Setting the fence is easy; the precise adjustment facilitates great accuracy. The rip fence drops down clear of the machine table level to free up extra space for dividing large panels.

Crosscut fence with fixed 90° angle

Stops to 3,200 mm

The crosscut fence with fixed 90° angle earns its keep every day by helping with precision cuts on workpieces of different lengths and formats. The fence can be easily slid from front to back without lifting. Adjustment using graduated scale.

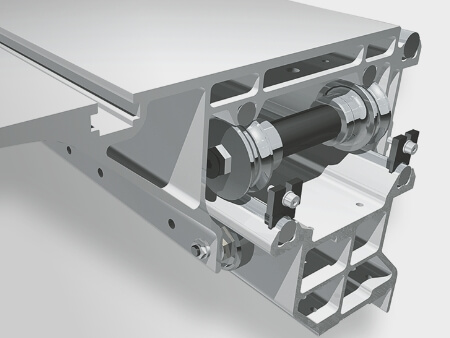

Sliding table

Table length 3,000 mm

The large dumbbell rollers guide the moving table with absolute precision between the hard-chromed guide bars. Robust though it is, the table responds even to a light touch, gliding smoothly and securely as if it were on rails. And it retains this ease of movement even after decades of hard work, dust and dirt.

Control panel on the machine frame

All functions are easily accessed on the control panel on the machine frame. You can control the rise/fall and tilt of the main saw blade at the touch of a button. The tilt angle is shown on the digital display.

Saw blade projection

The saw blade projection of the WA 80 is 150 mm (saw blade diameter 450 mm).

Rip fence with precise manual adjustment

Cutting width 1,000 mm

Setting the fence is easy; the precise adjustment facilitates great accuracy. The rip fence drops down clear of the machine table level to free up extra space for dividing large panels.

Crosscut fence with fixed 90° angle

Stops to 3,200 mm

The crosscut fence with fixed 90° angle earns its keep every day by helping with precision cuts on workpieces of different lengths and formats. The fence can be easily slid from front to back without lifting. Adjustment using graduated scale.

Sliding table

Table length 3,000 mm

The large dumbbell rollers guide the moving table with absolute precision between the hard-chromed guide bars. Robust though it is, the table responds even to a light touch, gliding smoothly and securely as if it were on rails. And it retains this ease of movement even after decades of hard work, dust and dirt.

Motor rating

4 kW (5.5 HP) with single speed (4,000 rpm)

Powerful and smooth-running The saw is a powerhouse produced with the latest manufacturing technology. The saw shaft runs incredibly smoothly because it is electronically balanced as a fully assembled unit and extensive use is made of cast components. The high-precision vertical movement of the unit is linear with maintenance-free guide bearings. The robust tilt quadrants incorporate the traditional Altendorf tongue and groove connection system, which allows the whole unit to tilt easily and precisely to exactly the correct angle.

Sliding table

Table length:

- Table length 2250 mm

- Table length 3200 mm

- Table length 3400 mm

- Table length 3800 mm, with ground support

- Table length 4300 mm, with ground support

Accessories:

- On/off switch on the double trolley

Drive power and speed

- 5.5 kW (7.5 HP) with 3 speeds, 3/4/5000 rpm, manually adjustable

- Special voltage for 5.5 kW (7.5 hp), 3 speeds, 3/4/5000 rpm

- 7.5 kW (10 HP) with 3 speeds, 3/4/5000 rpm, manually adjustable

Scoring units and accessories

- Scoring unit with electromotive height and manual side adjustment

- RAPIDO-scoring system, adjustment range: 3 – 3.8 mm, ø = 120 mm

- LED lighting on the scoring unit

Parallel stops

with manual adjustment:

- Cutting width 800 mm, incl. fine adjustment, adjustable via scale

- Cutting width 1300 mm, incl. Fine adjustment, adjustable via scale

with DIGIT X:

- Cutting width 800 mm, manual adjustment with digital display, incl. fine adjustment

- Cutting width 1000 mm, manual adjustment with digital display, incl. fine adjustment

- Cutting width 1300 mm, manual adjustment with digital display, incl. fine adjustment

Angle stops

with DIGIT L:

- Lengths up to 3200 mm, length can be adjusted via digital display with fine adjustment

Angle mitre stop:

- Lengths of up to 3500 mm, manual angle adjustment by 49°, with length compensation

- with DIGIT L, lengths up to 3200 mm, length can be adjusted via digital display, angle dimension with length compensation adjustable via scale

- with DIGIT LD, lengths up to 3200 mm, length and angle can be adjusted via digital display, with integrated length compensation

Parallelogram Cross Slide (PQS):

- with digital angle display, lengths up to 3500 mm, manual adjustment, angle adjustment by 47° with digital display, length and angle measurement with length compensation, adjustable via scale, 2 individual tilt stops included

- with DIGIT LD, lengths up to 3200 mm, convertible stop, length and angle adjustable via digital display, with integrated length compensation, 2 individual tilt stops, fine adjustment, batteries and charging cable included

Accessories:

Cross slide extension for angle stop / angle mitre stop, extendable to 650 mm

Mitre stops

One-sided:

- Lengths up to 2500 mm

Double-sided:

- DUPLEX, lengths up to 1350 mm, adjustable via analogue angle and length scale with magnifying glass

- DUPLEX, lengths up to 2150 mm, adjustable via analogue angle and length scale with magnifying glass

- DUPLEX D, lengths up to 1350 mm, adjustable via digital angle display and analogue length scale, with length compensation

- DUPLEX DD, lengths up to 1350 mm, adjustable via digital length and angle display, with length compensation

Other accessories

- PALIN/parallel cutting device, adjustable via scale

- JETTY, second edition on the double trolley

- Front support roller

- Hold-down device, manual, clamping height up to 200 mm

- Additional cross slide with double bottom support roller

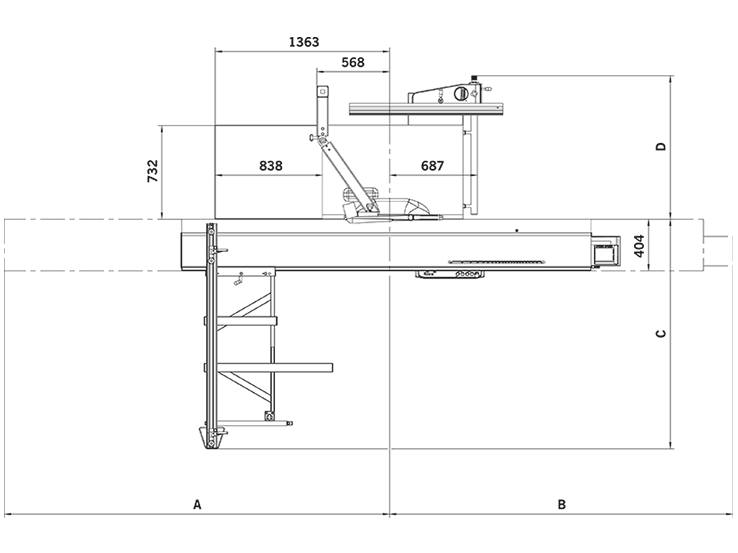

A – Trolley length + 290 mm

B – Trolley length + 360 mm

C – Angle stop, lengths up to 2500 mm: 1500 – max. 2630 mm

C – Angle stop, lengths up to 3200 mm: 1890 – max. 3420 mm

C – Angle mitre stop, lengths up to 3500 mm: 1960 – max. 3690 mm

D – Cutting width + 310 mm

Machine Weight – from 1000 kg

Working table height – 910 mm