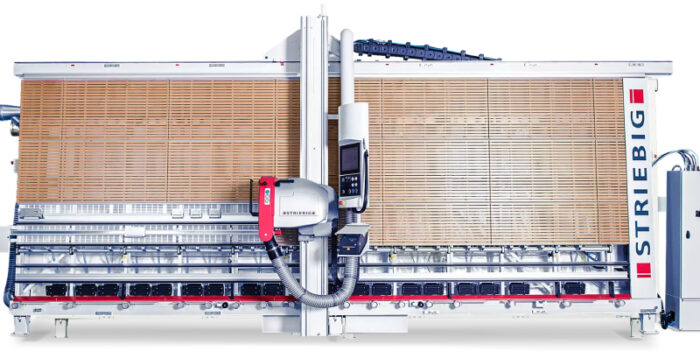

Striebig Control

CONTROL – cutting technology meets ergonomics and intelligence

The CONTROL is already well-equipped when it leaves the factory. A 12" touch screen computer and the modern machine software ensure perfect operating comfort in every detail. The automatic saw swivelling is just one of the many functions that make panel cutting ergonomic and comfortable. Intelligent options allow you to achieve a high degree of automation of the sawing process and to integrate CONTROL into the operational data flow.

If you have questions, or would like more information, please fill out our contact form.

Highlights of the STRIEBIG CONTROL

Cutting technology meets the future

The CONTROL defines the premium class for vertical sawing technology through a high degree of sawing process automation and innovative equipment options. The intelligent visualisation on the clearly arranged 12" touch screen computer guides you safely step by step through the cutting process.

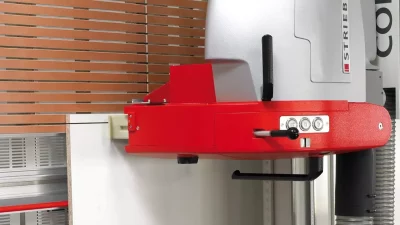

Modern STRIEBIG operating unit (HMI)

With the logically designed user interface, you can control the CONTROL easily and conveniently via a 12" touch screen.

Electronic positioning system EPS-Y and ABO – top trimming

Thanks to the standard EPS-Y you can automatically position the saw unit for horizontal sawing. The ABO, which is also a standard feature, ensures the automatic top trimming cut.

Comprehensive standard equipment

- 12" inch touch screen computer with optimal user guidance

- Laser-supported display of the horizontal cut

- Digital measuring system DMS-X

- Electronic positioning system EPS-Y incl. automatic top trimming cut ABO

- Automatic saw beam locking with interface recognition

- Automatic locking and swivelling of the sawing unit

- Automatic insertion and removal of the sawing unit

- Automatic panel end recognition

- Fully automatic sawing sequence

- Selectable sawing cycle

- Pneumatic clutch for easy changeover to manual operation

- Operating time counter

- Tool database

- ALU centre support over the entire machine length

- Integrated, particularly powerful TRK dust extraction. Dust limit value around 1 mg/m³

- Super-silent noise insulation

- Network connection

- UPS 24VDC for Touch-PC (uninterruptible power supply)

STRIEBIG ExpertCut Con

The 'professional' version for the STRIEBIG CONTROL

Transfer parts lists from standard ERP or CAD systems and optimise them with the STRIEBIG cutting optimisation software directly at your office workstation. You can also process and manage order, material and parts lists with the program.

The scope of supply includes:

- Electronic positioning system EPS-X

- Automatic saw beam positioning ASP

- Software package (operator guidance with STRIEBIG ExpertCut Con)

- Software license for 1 office workstation (network license)

- Label printer

- Connection option for network connection via LAN

- Operating instructions

- Paper holder

STRIEBIG BaseCut Con

The 'light' version for the STRIEBIG CONTROL

You create simple parts lists and automatically and easily optimise the cutting directly via the 12" touch screen panel of your STRIEBIG CONTROL. The intelligent visualisation on the touch screen guides the operator through the cutting process, step by step.

The scope of supply includes:

- Electronic positioning system EPS-X

- Automatic saw beam positioning ASP

- Software package (user interface with STRIEBIG BaseCut Con)

- Label printer

- Connection possibility for network connection via LAN

- Operating instructions

- Paper holder

STRIEBIG OptiDivide cutting optimisation

The retrofittable version

With OptiDivide you can achieve a higher degree of automation in panel cutting. The system works independently of the machine control. It can be retrofitted to many STRIEBIG models.

The scope of delivery includes:

- Compact aluminium housing with integrated 12" touch screen panel

- Label printer (installed and protected in the housing, operated by means of a drawer)

- Network connection via wireless network

- Software package STRIEBIG cutting optimisation, incl. 1 network license for office workstation

- Power cable

- Mounting adapter for the corresponding STRIEBIG model

- Operating instructions

Increased feed speed

0.1 - 25 m/min

The current feed rate is shown in the display. It can be accessed and adjusted through the menu.

Provide machine data

I 4.0 ready

With this accessory, relevant machine data such as machine running time, engine hours, mains hours, date, time and status are written to a .csv file. This data is available to higher-level systems (not included in the scope of delivery) for evaluation in real time.

Provide production and machine data

I 4.0 ready

Only in combination with the ExpertCut option can production data such as the number of parts to be produced, number of cutting plans, number of finished cut parts, number of open parts, a part ID per element, as well as date, time and status be written to a .csv file together with the other machine data. This data is available to higher-level systems (not included in the scope of delivery) for evaluation in real time.

Horizontal separation of the frame

Optionally, the saw frame can be produced horizontally and separately. This results in smaller transport units, which is especially useful when access to the installation site is difficult.

Cutting height limit of Y-axis

The cutting height in the Y-axis can be reduced, e.g. in case of limited room height (option only possible in combination with the EPS-Y limited room height option). A precise clarification on site by your STRIEBIG sales partner is necessary for this.

Additional EPS-Y limited room height

The special EPS-Y for use where room height is limited.

Control cabinet installation variant 3

Special installation variant of the control cabinet

Control cabinet on the left of the saw frame instead of on the right.

Control cabinet installation variant 6

Special installation variant of the control cabinet

Control cabinet set off to the right of the saw frame. Maximum cable length 5000 mm

Control cabinet installation variant 7

Special installation variant of the control cabinet

Control cabinet set off to the left of the saw frame. Maximum cable length 5000 mm

Special voltage

The saw motors and controls can be built for country-specific operating voltages.

Tropical insulation

For tropical regions, the saw motor can be equipped with a special insulation against higher humidity and against damage by termites.

The original in vertical sawing technology

STRIEBIG – the original in vertical sawing technology. Invented by our company founder and pioneer Ludwig Striebig, it is the ideal combination of precision and economy. In many fields of application, STRIEBIG panel saws are the only possible cost-effective and space-saving solution for panel cutting.

More than

49.500

STRIEBIG vertical panel saws produced

Average of

15.400

operating hours per STRIEBIG life cycle

Cutting capacity of more than

1.000.000

sawn parts per STRIEBIG life cycle

STRIEBIG panel saws: maximum quality and durability

Minimum space requirement

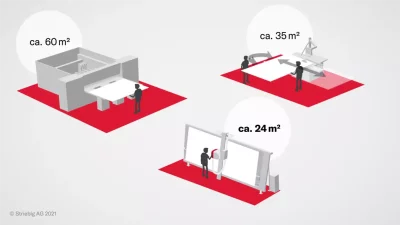

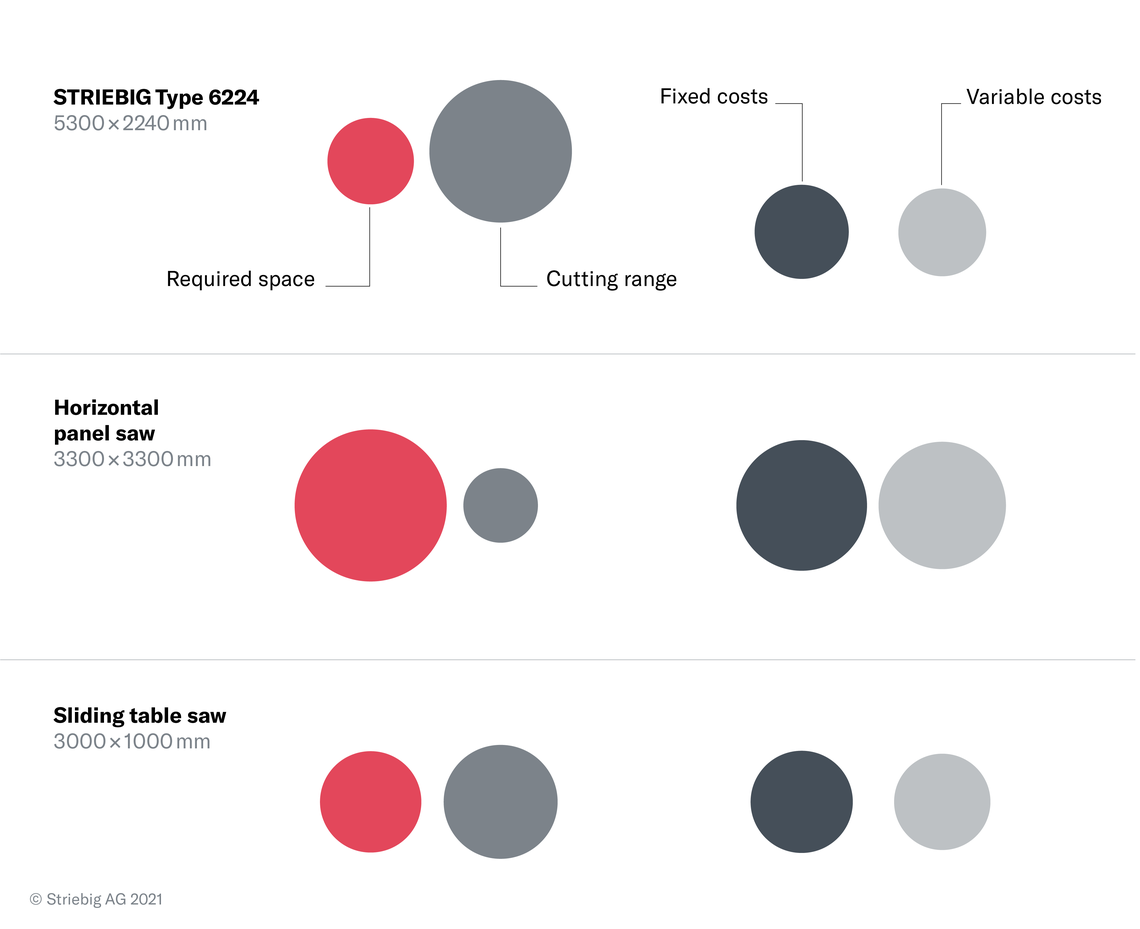

In contrast to a horizontal panel-sizing saw, the vertical STRIEBIG panel saw only requires about half the space. The area of a STRIEBIG including space in front of the machine for handling and feeding the panels is approximately 24 m2. A horizontal panel saw with a cutting range of 3300x3300 mm requires about 60 m including space for handling and feeding the panels2. If you also consider the advantage that panels up to 5300 mm in length can already be processed on a STRIEBIG in standard size, the vertical sawing technology shows its “space advantage” even more clearly.

Optimal value for money

Compared to other vertical panel saws, STRIEBIG saws already offer many accessories in the basic equipment. From the simple, hand-guided STRIEBIG to the high-end sawing centre with continuous data flow in production, the variety of vertical cutting technology is convincing in the various application areas of wood, plastic and composite panel processing. Low space requirement costs, low maintenance and service costs, as well as a high value retention of the investment further contribute to the optimal value for money of STRIEBIG panel saws.

Convincing customer satisfaction

Thanks to our decades-long leading market position, we have been able to continuously expand our customer base and enjoy above-average customer satisfaction. In cooperation with users and specialist trade partners, we are constantly further developing our machines. Thus our customers continuously benefit from more advantages of vertical sawing technology.

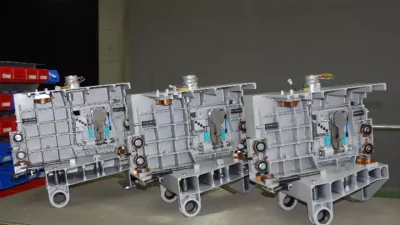

Produced in-house, Swiss-made in Lucerne

With enthusiasm and passion, the team at Striebig AG develops and produces the Swiss-made vertical panel saws at the production plant in Lucerne. We always keep an eye on the overall economic and ecological context of our activities. Our entire company is certified for its management systems in the areas of quality, environment, occupational health and safety and health protection.

| Weight of the saw | approx. 1.200 kg |

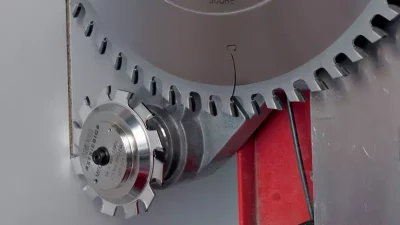

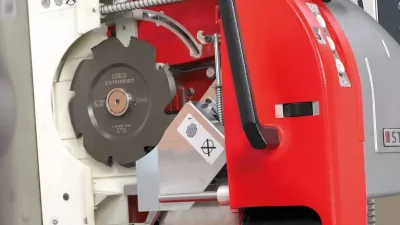

| Cutting depth | 80 mm *1 |

| Saw motor power | 5.5 kW (7.5 HP) |

| Saw blade diameter | 300 mm |

| Saw blade bore | 30 mm *2 |

| Emission sound pressure level at the workplace LpA | 83 dB *3 |

| Saw blade speed | 4800 rpm |

| 1 extraction connection | ø 140 mm |

| Compressed air connection | 6-10 bar |

| Wattage | 7.5 kW |

| Wattage with option 4SB | 10.4 kW |

| Mains connection | 3 x 400 V / 50 Hz |

*1 Option: 103 mm · *2 with 2 side holes Ø 9 mm, radius 30 mm · *3 Measurement standards and emission values according to EN 1870-14, measurement uncertainty allowance K = 4dB (A). (All data refers to CONTROL type 6224)

The following applies to all machines:

Efficient TRK dust extraction system significantly below 2 mg/m3. The system used must have an extraction performance of 20 m/s in order to meet the TRK specifications. (Vacuum approx. 1400 Pa. / COMPACT approx. 1470 Pa) at the connector in order to meet the TRK specifications.

Technical note:

Permissible ambient temperature min: + 5 °C / max. + 40 °C

Relative humidity: 19 - 95% without condensation

In case of mains fluctuations greater than +/- 10% of the nominal voltage, a voltage stabiliser must be installed at the place of use.

The technical specifications are approximate values.

We reserve the right to make changes due to further developments.

Dimensions in mm

| Type | L* | H | T1 free | T2 Wall |

|---|---|---|---|---|

| 6224 | 7153 | 3035 | 1741 | 1361 |

| 6216 | 7153 | 2951 | 1700 | 1354 |

| 6168 | 7153 | 2477 | 1500 | 1312 |

| 5224 | 6153 | 3035 | 1741 | 1361 |

| 5216 | 6153 | 2951 | 1700 | 1354 |

| 5168 | 6153 | 2477 | 1500 | 1312 |

| 4224 | 5153 | 3035 | 1741 | 1361 |

| 4216 | 5153 | 2951 | 1700 | 1354 |

| 4168 | 5153 | 2477 | 1500 | 1312 |

* L = Total length of the machine, including control cabinet

Cutting area in mm

| Type | LS | HS vertical | HS horizontal |

|---|---|---|---|

| 6224 | 5300 | 2240 | 2100 |

| 6216 | 5300 | 2160 | 2016 |

| 6168 | 5300 | 1680 | 1540 |

| 5224 | 4300 | 2240 | 2100 |

| 5216 | 4300 | 2160 | 2016 |

| 5168 | 4300 | 1680 | 1540 |

| 4224 | 3300 | 2240 | 2100 |

| 4216 | 3300 | 2160 | 2016 |

| 4168 | 3300 | 1680 | 1540 |